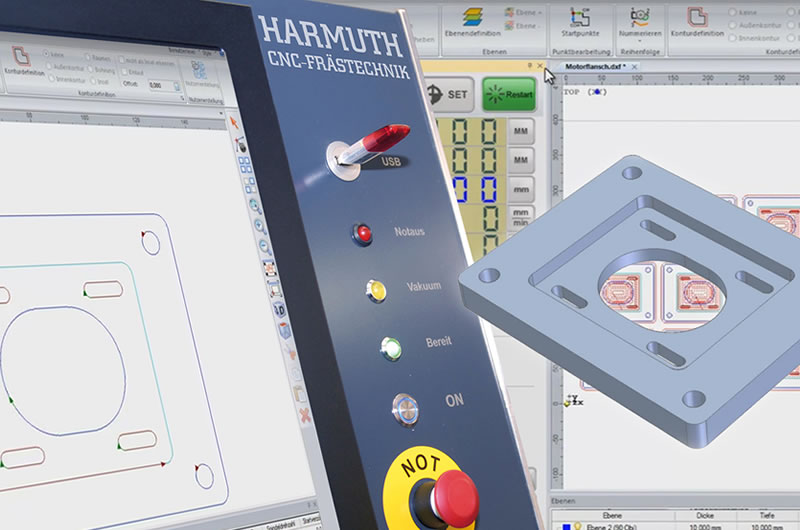

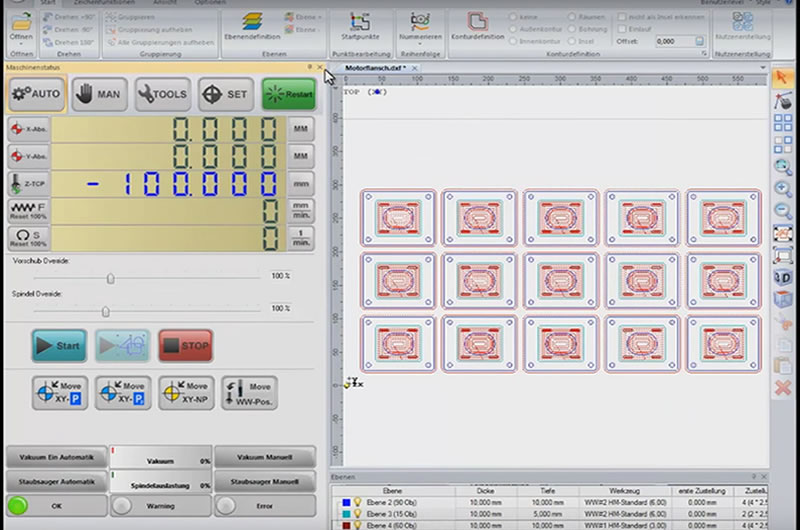

A modern system – customized to your needs

Easy to use and straight forward Application-Software

The CNC controlling system of Penta-Tec (www.penta-tec.com)

is supplied with all our machines.

The many presets that you can use to start milling immediately should be interesting for beginners and professionals alike.

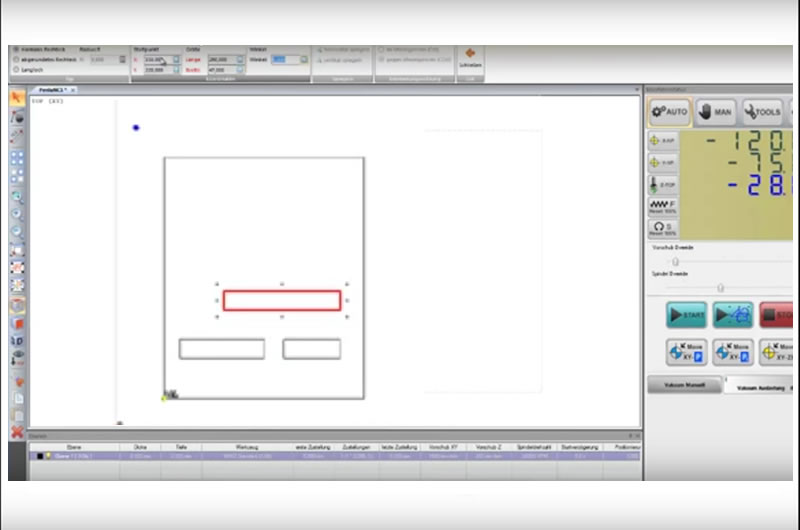

The software is easy to use and structured straight forward.

Working with our CNC routing machines is particularly efficient with the clear user interface.

An assistant guides you step by step through our software and facilitates the creation of milling tasks.

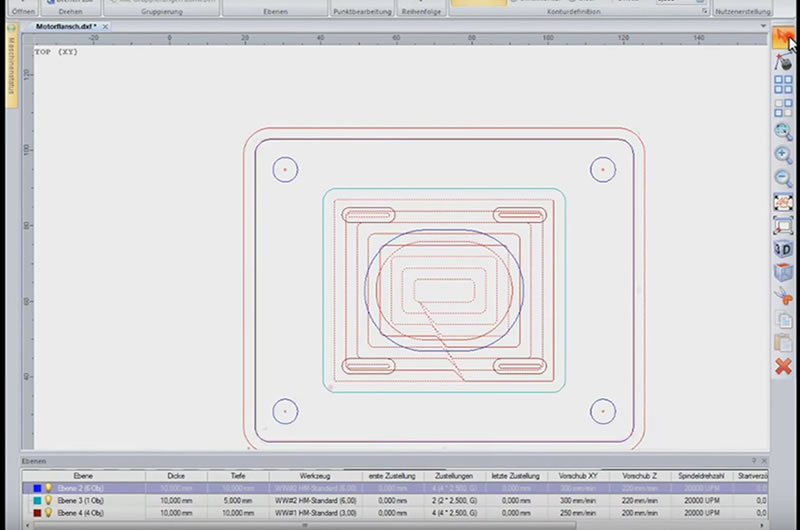

important functions – Overview:

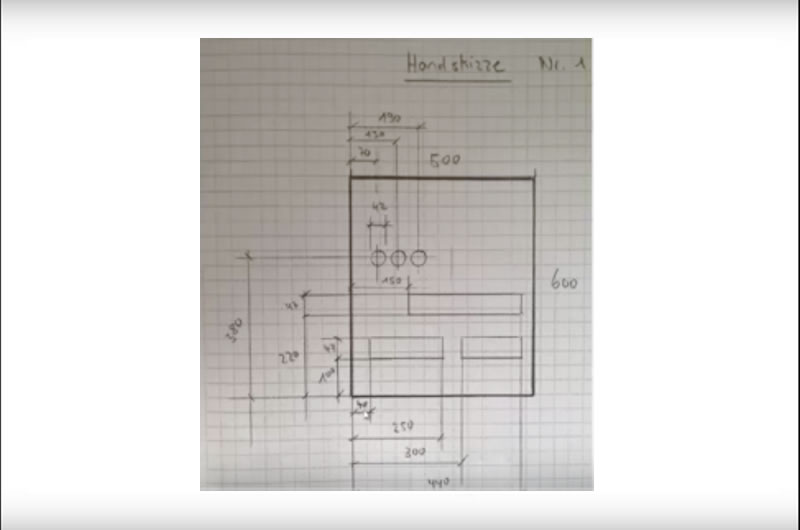

Opening NC codes and DFX files

Graphic representation of objects

Drawing function

Material and tool management

Rotating, mirroring, duplicating, panel creation

Plane assignment, starting point, numbering

Contour definition (inside, outside, rooms, islands, drilling, thread cutting)

Automation (e.g. starting point, contour assignment, numbering)

Electronic table levelling

Several tangential axles are possible

Recognition and correction of fudicual marks

Measuring probe for tool lenght measurement

Intelligent management of the tool changer

Approaching and saving of component contours

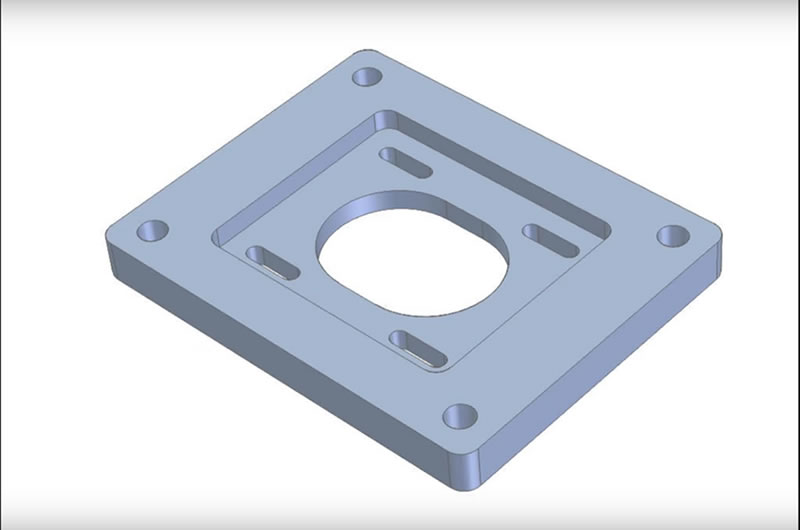

Milling files processing simplyfied !

Many presets and a clear user interface of the CNC-Penta-Tec software deliver fast results so you can start milling right away.

Please regard to the training videos for usage!

CNC-Pentatec – automatic tool measurement

With first time equipping the tools are placed in tool saver.

In the presets for tool changer the tools are assigned to stations. All new tools are separated.

By pressing the tool button all tools get measured automatically and the gathered data is being saved.

With the first milling tool the zero point is approached and all other tools are adjusted in the same height. The different tool lenghts are calculated to the zero point.