We offer a big sortiment of equipment for every machine

Our tool changer as a special Highlight !

The tool changer disappears completely under the table. Depending on the table size, between 5 and 14 tools are stored here, which are automatically utilised.

The functionality

With the first time equipping the tools are stored in the tool changer. In the settings of that, the tools are assigned to the stations.

All new tools are selected. Now a click on the button „measure“ is necessary and all tools are measured and saved automatically in the tool test buttons.

With the first milling the zero point is approached, all other tools are setted on the same height. The different tool lenghts are directly calculated at the zero point.

If a tool is attrited, it is removed from the spindle with a button. The status immediately changes to „not measured“. If the tool should be used again, is has to calibrate automatically. Otherwise there is no possibility to mill with this tool.

Standard equipment :

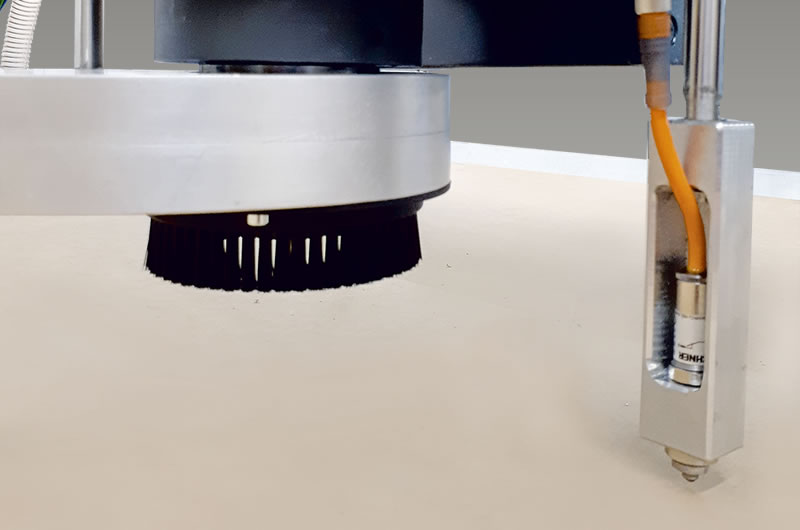

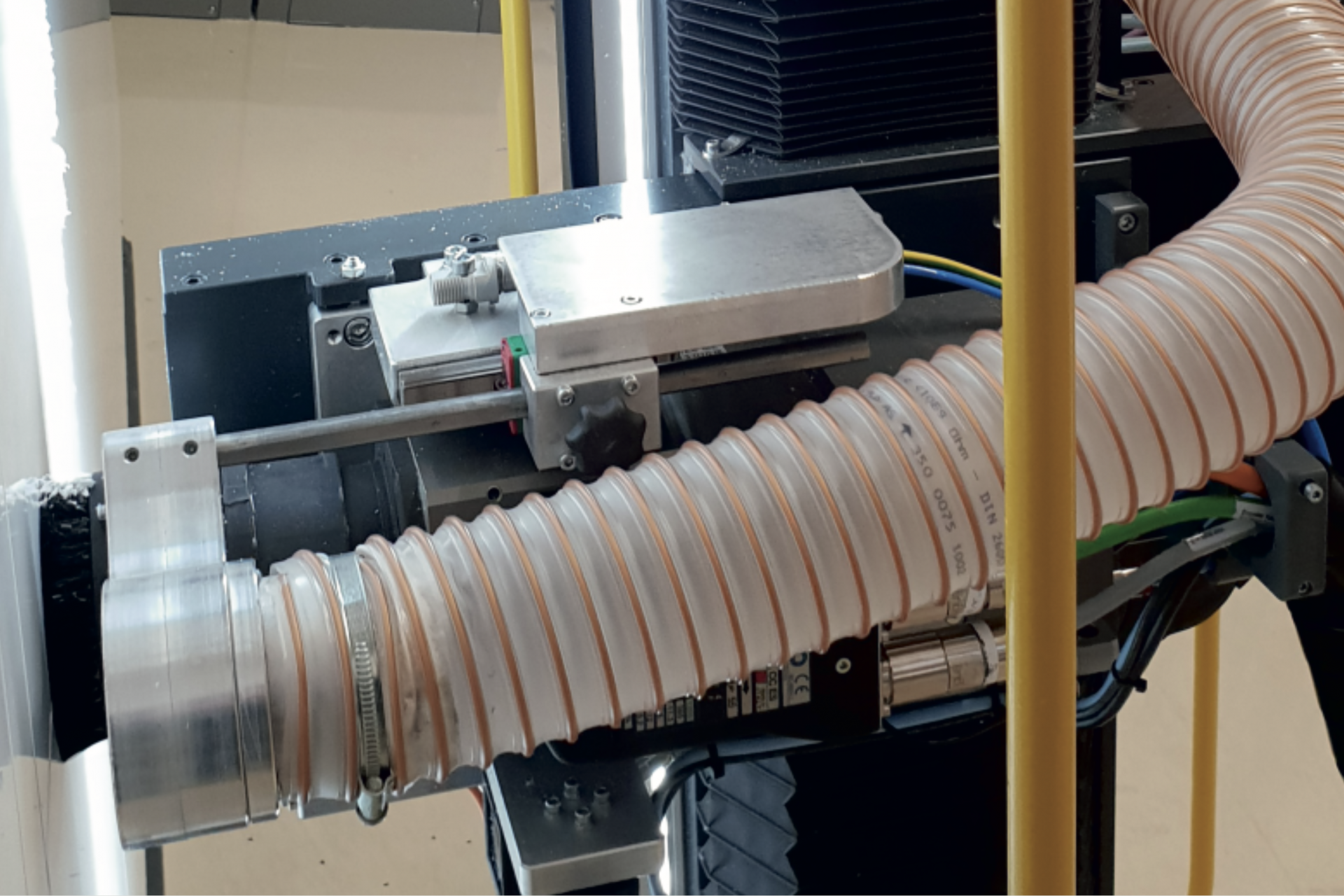

Suction device

Suction device

Our machines include a suction system (without vacuum cleaner)

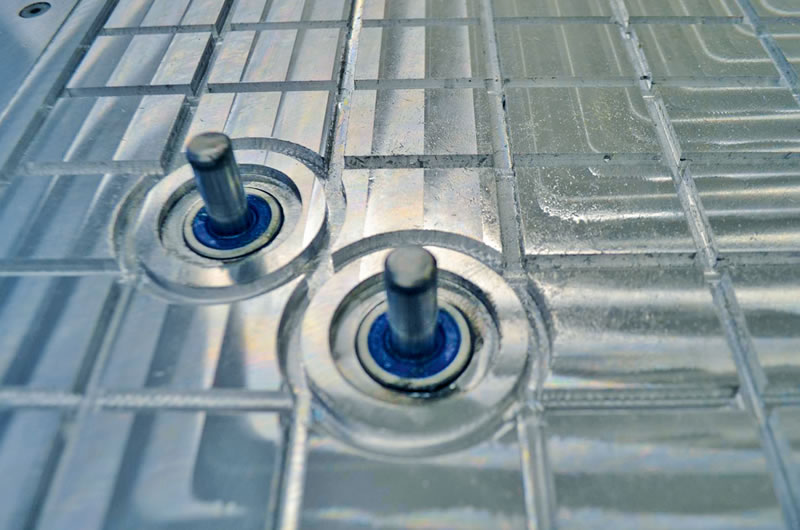

Vacuum table

Vacuum table

Vacuum table manufacture of cast aluminium. Because of the vacuum the material will be sucked in and prevented, that the building parts slip out of position during milling. The vacuum areas can be configurated by ball valves.

Permanently installed control computer (depending on model)

Permanently installed control computer (only F + Vertikal, Vertiform and Profi-Serie 1+2)

An industrial computer installed in a control terminal with a built-in touch screen 21``, TwinCat operating system with Windows, Machine control software ``Penta-Tec`` with very simple operating functions and many automatic functions, drawing functions, contour calculations, DXF, s4m and G-code import, 3D processing, automatic plane and milling cutter assignment from a DXF

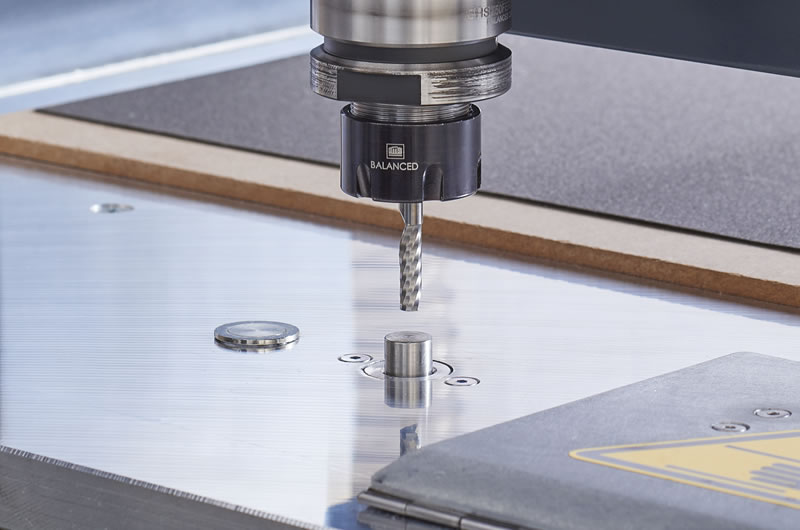

Tool lenght sensor

Tool lenght sensor

determines the z-zero point.

After clamping the milling cutter, the z-height is automatically corrected to table height via the measuring probe. Another measuring is not more necessary.

Optional equipment :

Remote control

Remote control

- Approaching and saving the exact positions and zero points

- Milling by hand with the remote control

- Changing feed rates and rotational frequencies during the milling work

- turn on and off of additional aggregates

- implement customer specific special functions

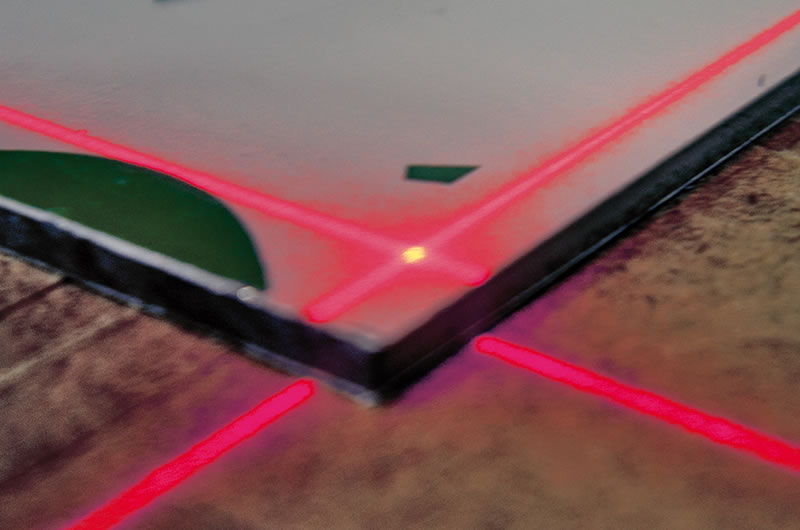

Cross laser

Cross laser

For simple, optical determination of a zero point. The cross laser enables more precise, manual approach to a desired position. With the software, the position can be defined as a zero point.

Height mesurement

Height mesurement

Correction of the height of the table and height sensing of workpiece surfaces for same milling depth

Spraying system „Fogbuster“

Spraying system „Fogbuster“

Magnetic valves with 2 tubes are integrated in the machine and the spraying mist will be controlled to turn on and off together with the milling spindle with the software.

Benefit: No mist! Sprayed in drops

Vacuum pump Busch Mink MV 0312B

Vacuum pump Busch Mink MV 0312B

60 Hz, 345 m3 / h, 850 mbar, 6.5 kW

Very quiet (69dB) regulated by a frequency converter. Extremely energy-saving through software control.

large parts = low pressure

small parts = high pressure

Reduced pressure can be activated if milling is not performed

Idustrial vacuum profi

Idustrial vacuum profi

Optimal for plastics and aluminium processing

- Recommend for continuous operation

- Very quiet

400V, 3kW, 100 Litre, 310mbar

- More pumps connectable

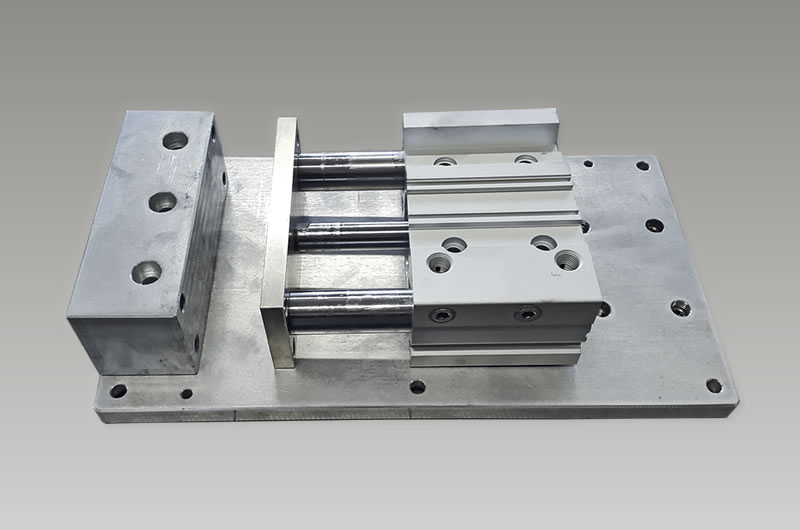

Pneumatic vice with cylinder

Pneumatic vice with cylinder

Base plate 20mm aluminum, stop w ith thread for clamping jaws, cylinder can be screwed on in 3 fixed posit ions.

(Clamping range up to 150mm, stroke 50mm)

This device can be fixed on the table at specified intervals via 2x dowel pins w ith bushes (in the table) and 6x M8 mounting holes w th threaded inserts (in the table) including valve with shut-off option, hoses and accessories, aluminum clamping jaws.

Rollable control unit

Rollable control unit

Terminal including touch PC with the latest technology for operating the milling machine.

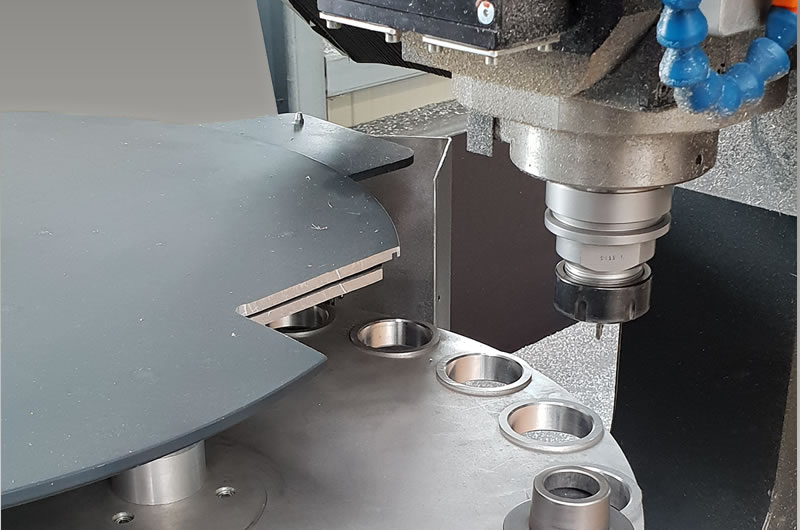

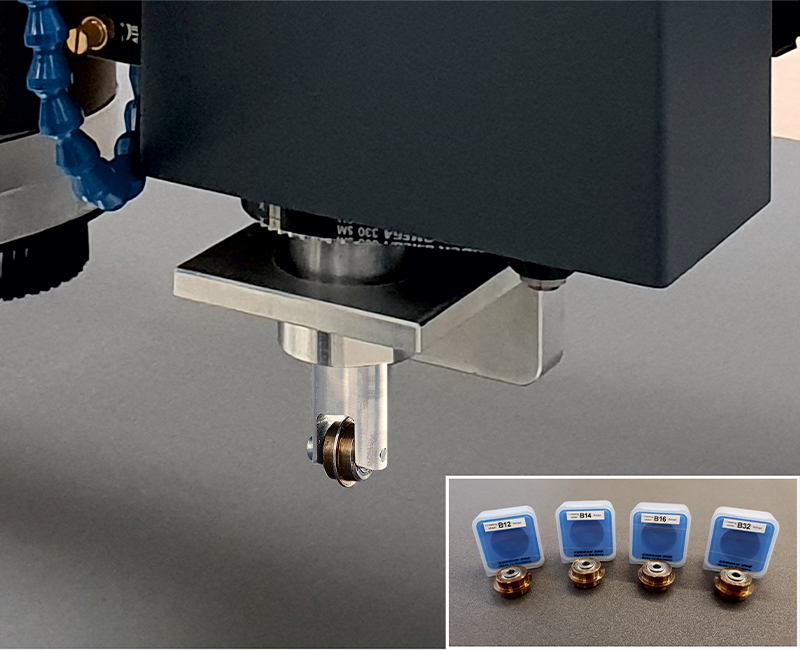

Tool changer

Tool changer

The tool changer is completely hidden under the table. 10 to 14 tools (or double tool changers) are stored here, which are automatically utilised

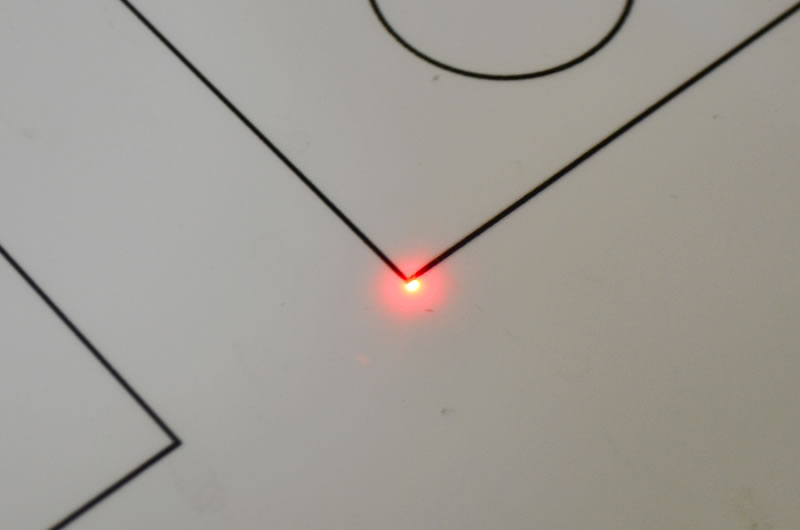

Point laser

Point laser

For simple, optical determination of a zero point. The point laser enables more precise, manual approach to a desired position. With the software, the position can be defined as a zero point.

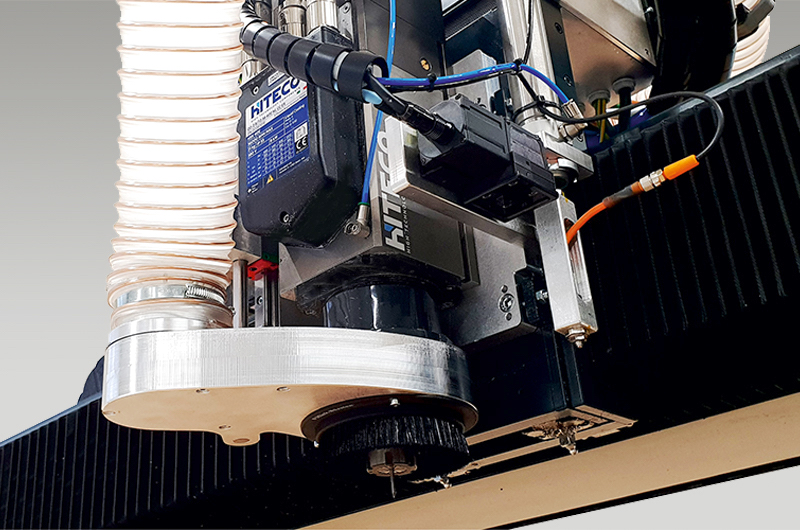

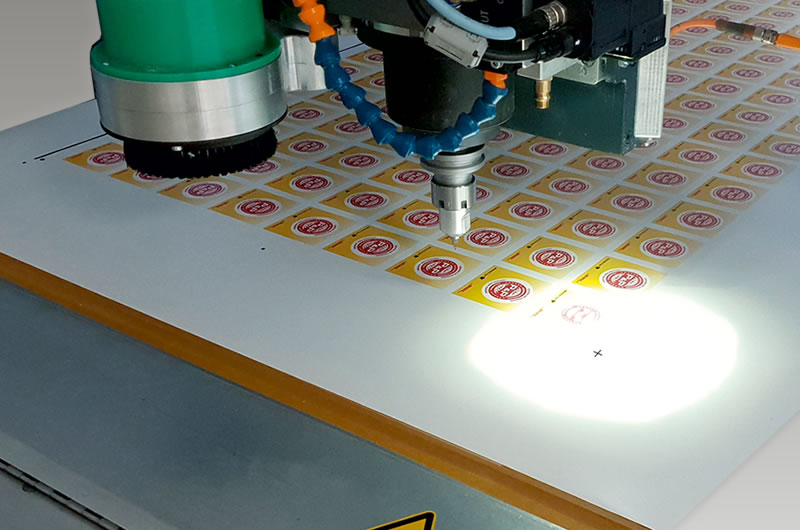

Fiducial recognition camera

Fiducial recognition camera

camera system for recognition of fiducial marks and correction of milling data. (This system is integrated in our software – there will not installed a second software)

Vacuum pump Becker 4kW

Becker SV 8.190 / 2-48 Pressure-regulated vacuum pump 4kW

175m3 / h -380 mbar

up to 100hz

4.0 kW

Frequency-controlled and via software

large parts = low pressure

small parts = high pressure

Automatic vacuum valves

Automatic vacuum valves

Fields of vaccum can turn on via user interface in the software - automatically switch on and off in the area, where the machine is milling.

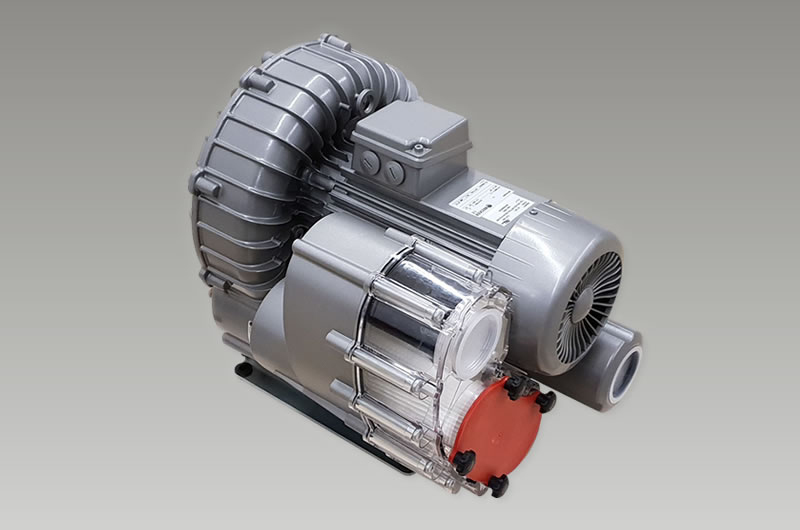

Idustrial vacuum profi - frequency controlled

Idustrial vacuum profi - frequency controlled

Professional industrial vacuum cleaner for the efficient removal of steel, aluminum and plastic chips

- Turbine with side channel blower

- High performance even in continuous operation without maintenance requirements

- Quick opening of the container

- Integrated pneumatic filter cleaning

- 400V, 4kW, 100 liters, 310mbar

LED light bar

LED light bar eXtreme-Line

6000k white matt diffuse SMD LEDs

The perfect work lighting

Notebook

Notebook

state of the art technology

Carousel change

Carousel changer driving with the portal

Drives pneumatically from the work area so that no travel is restricted and a langer component can be pushed through, including control electronics, valves, software expansion and safety devices such as querying the frequency converter whether the motor is at a standstill.

Zero stop

Zero stop

Zero stops are activaded via touchscreen or button. With activity the cylendrics are going pneumatic out of the table, the zero point of these stops is automatically transferred into the software (adjustable). At the start of milling the stops get lowered into the table automatically.

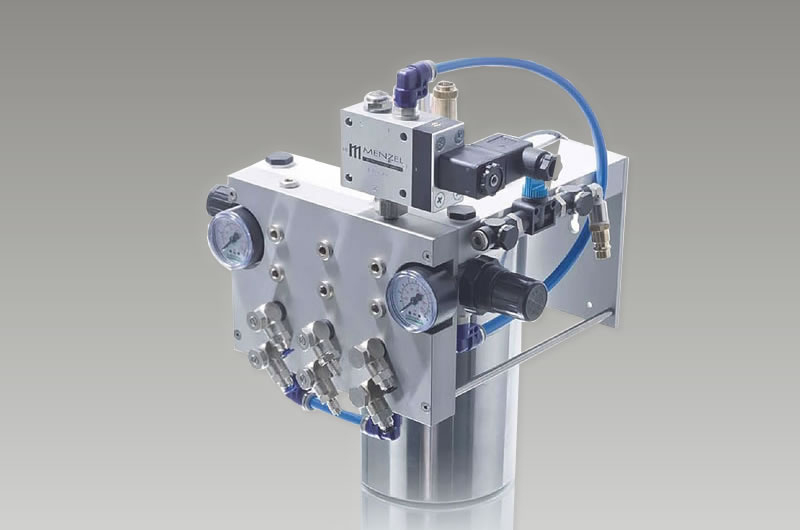

Spraying system ``Menzel``

Spraying system ``Menzel``

With 1 nozzles adjustable via articulated, joints with complete pressure unit, hoses, valves

Vacuum pump Becker 4,8kW

Becker SV400 / 2 pressure-regulated vacuum pump 4.8kW - two-stage

235m3 / h -400 mbar

60hz

4.8 kW two-stage

Frequency-controlled and via software

large parts = low pressure

small parts = high pressure

Idustrial vacuum

Idustrial vacuum

Cheap industrial vacuum. Ideal for advertising technican. Not recommend for continuous operation. Vacuum sucker with carbon brushes. 3X1200 Watt, 80 Litre, 270mbar. Optimal for plastics and aluminum processing.

Additional axes (2nd / 3rd milling spindle)

Additional axes (2nd / 3rd milling spindle)

Regardless of whether several milling spindles or other units.

We can install additional axes for you in the Profi series.

Ask us.

T-slot table

T-slot table

The perfect supplement and assistance for clamping workpieces.

Trolley N1100 700A

Trolley N1100 700A

Milling spindles :

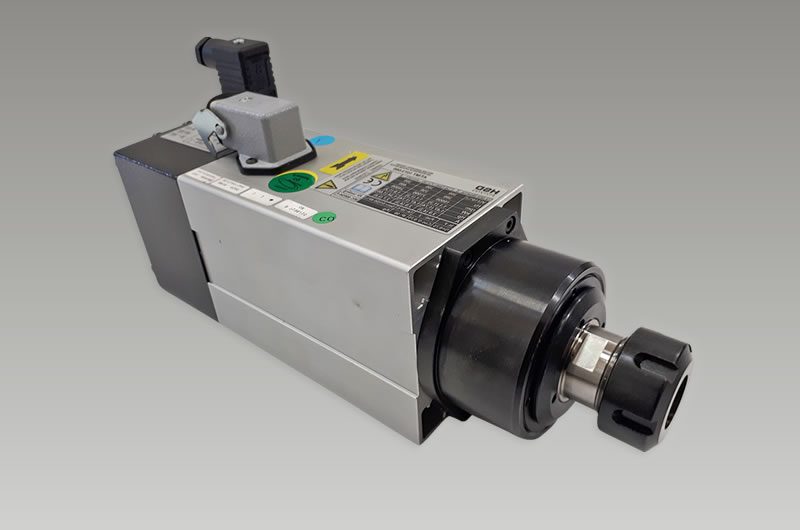

HSD milling spindle MT 1073 (24.000U/min)

HSD milling spindle MT 1073 (24.000U/min)

Manual change of tools, 24, 0 00 rpm, 1.1 kW, 300 - 24, 0 0 0 rpm w ith frequency converter (speed is controlled by the software), complete set of colletses

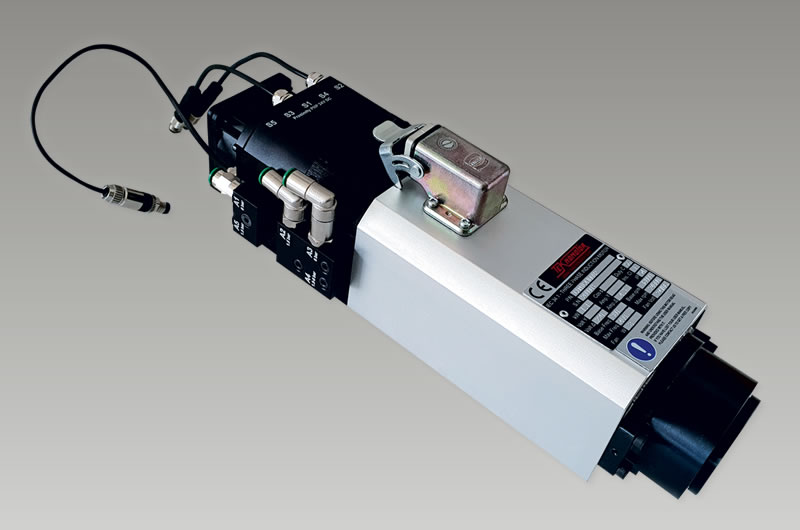

Milling spindle Teknomotor (1,1kW, 24.000U/min)

Milling spindle Teknomotor SK 20-ER16 (1,1kW, 24.000U/min)

Pneumatic tool change

24.000 U/min | 1,1 kW | 230 V

Steel bearing, ``tool clamped`` sensor

clamping range from 3 to 10 mm

The speed is controlled by software

Milling spindle Teknomotor (2,2kW, 24.000U/min)

Milling spindle Teknomotor SK 20-ER16 (2,2kW, 30.000U/min)

Pneumatic tool change,

30.000 U/min | 2,2 kW | 230 V

Ceramic bearing, ``tool clamped`` sensor

Clamping range from 3 to 10 mm

The speed is controlled by software

Milling spindle HITECO PT300 (24.000U/min)

Milling spindle HITECO PT300 L/4/24 SK30 (24.000U/min)

With frequency converter (speed is controlled by the software)

bearing in front ceramic / rear steel

pneumatic tool change

3 sensors

Clamping range from 3mm to 16mm

(20mm depending on the ER25 or ER32 system)

Milling spindle HITECO PT400 (24.000U/min)

Milling spindle HITECO PT400 L/8,5/24 SK-30 (24.000U/min)

Output 8.5kW, 4-pole motor, 380 V air-cooled, bearing in front ceramic / rear ceramic; Pneumatic tool change, 4 sensors, incl. Servo amplifier, cooling unit and all assembly parts, with encoder, (controlled milling spindle) Advantages: With this spindle (one unit) all functions can be used. Milling / cutting / creasing / V-cut. Real thread cutting without length compensation. The complete work area is available!

Milling spindle HITECO PT250 (36.000U/min)

Milling spindle HITECO PT250 W/8/36 HSK-E40/F50 (36.000U/min)

Output 8.0kW, bearing in front ceramic / rear ceramic, Pneumatic tool change, 4 sensors, incl. Servo ampl ifier, cooling unit and all assembly parts, w ith encoder (controlled milling spindle) Advantages: With this spindle (one unit) all functions can be used. Milling / cutting / creasing / V-cut. Real thread cutting without length compensation. The complete work area is available!

No suitable spindle for you ?

At the customer’s request, we also install spindles from other manufacturers

(no stock items)

Conical holders :

Cutting tools – application via C-axis

A module for different tool types including a quick-change system

(Attention: the whole work area cannot be used)

Standard module tangential knifes

Standard module tangential knifes

Controlled via the C-axis.

Tangential knife for cutting rubber, kappa, cardboard, magnetic foil, soft plastics or similar materials.

The knife is controlled tangentially via a 5th axis.

Caution: The entire work area cannot be used!

Extension module oscillating knifes

Extension module oscillating knifes

Controlled via the C-axis.

For cutting cardboard, rubber and similar materials.

The knife is controlled tangentially via a 5th axis and driven by compressed air to 9,000 strokes / min with a 9mm strake.

Caution: The entire work area cannot be used!

Extension module scoring wheel ( different wheels available)

Extension module scoring wheel ( different wheels available)

For creasing e.g. cardboard boxes and soft plastics.

Caution: The entire work area cannot be used!

Cutting tools – application at

encoder-controlled milling spindles: HITECO PT250 / PT400

(only available for the following milling machines: Profi series 1 + 2 / Vertiform)

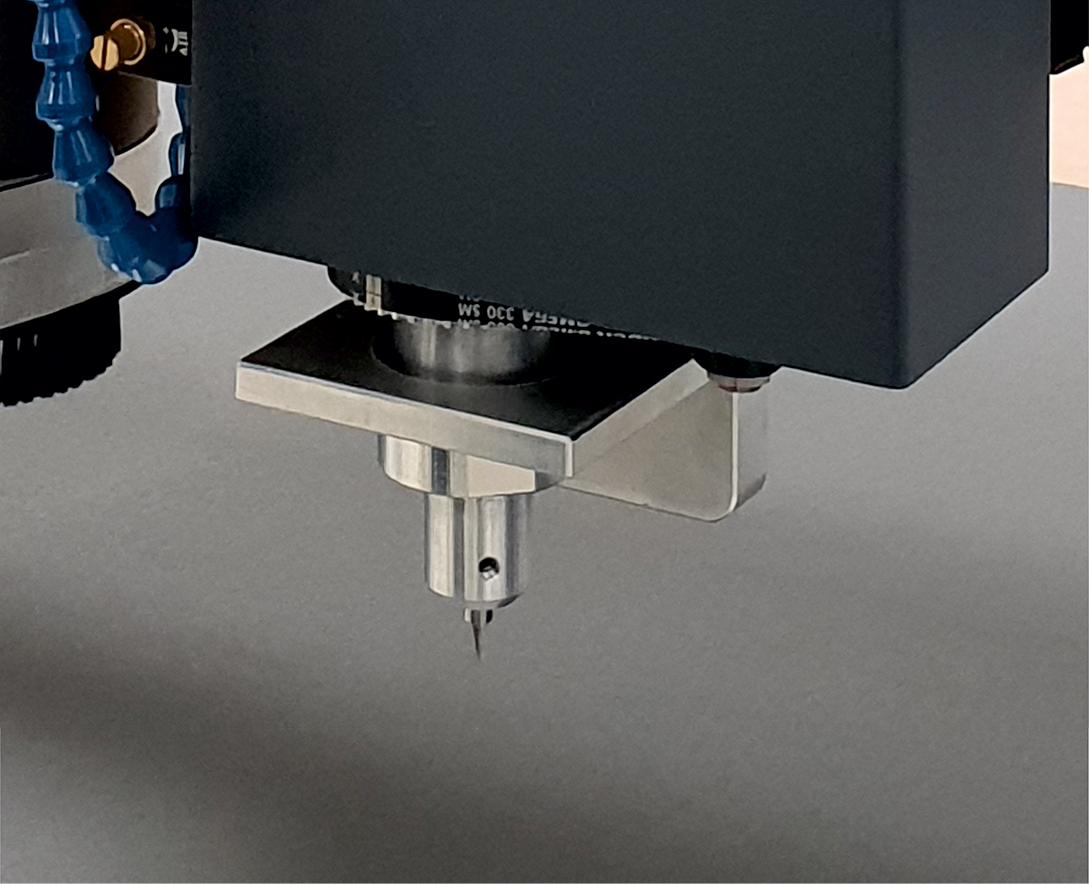

Oscillating blade

Oscillating blade

Because of the up and down movement of the blade, soft materials can be cutted f.e. Plastics, foam and cartonage. The blade is powered with compressed air on 9.000 strokes/min at 9mm stroke

Scoring wheel

Scoring wheel

For cutting of gum, kappa and similar materials or grooving cartonage. Different scoring wheel available.

Thread cutting

Thread cutting

Because of the additional processing options in our software, you can cut real threads without lenght compensation

V-Cut blade

V-Cut blade

The V-Cut blade is perfect for creating bevel cuts or V-slots. You can create professional 3D contructions of sandwich- or leightweight foampanels

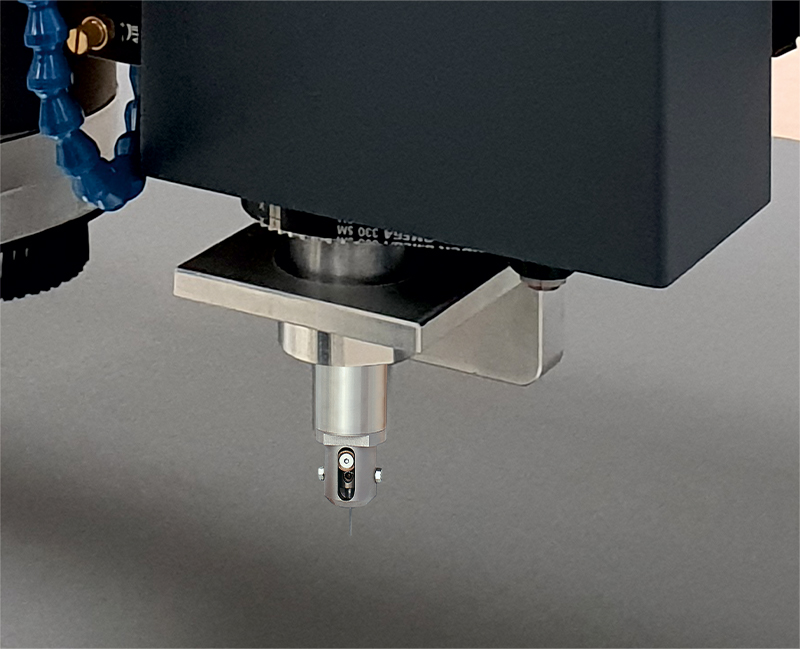

Tangential blade

Tangential blade

Tangential axis for scoring wheel, grooving tool or blade for cutting of gum, kappa and similar materials or grooving of cartonage. Blade is actuated with 5th axis tangential.

Attention: Not the whole workspace can be used!

Equipment options for the machines – at a glace

| Model | F+Serie / F+Vertikal Entry-level model with stepper motor technology (Closed loop systems) | Vertiform / Profi-Serie 1 for craft & industry with servo motors (Beckhoff) | Profi-Serie 2 for industry with servo motors (Beckhoff) |

| Equipment | |||

| construction | Machine base made of steel Heavy aluminum portal | Machine base made of steel Heavy aluminum portal | Machine base made of steel Steel reinforced portal for large heavy milling motors |

| Drives | Driven mother with closed loop stepper motors | Drives base ball screw with Servomotors (multiturn absolute value system) | X- and Y-axis via angular gear Z-axis via ball screw spindle |

| Vacuum table incl. | |||

| Tool changer | |||

| Tangentially controlled milling spindle (encoder-controlled milling spindle) | |||

| C-axis | |||

| Additional axes for 2nd / 3rd Milling spindle | |||

| Tangential knife | manual change via C-axis | automatic change via tool changer | automatic change via tool changer |

| Scoring wheel | manual change via C-axis | automatic change via tool changer | automatic change via tool changer |

| Oscillating knife | manual change via C-axis | automatic change via tool changer | automatic change via tool changer |

| V-cut knife | automatic change via tool changer | automatic change via tool changer | |

| "Dynacut" spray unit | |||

| "Menzel" spray unit | |||

| remote control | |||

| Zero point stops | |||

| Optical registration mark recognition | |||

| Point / cross laser | |||

| Height measurement Workpiece surface | |||

| T-slot table | |||

| Rollable control unit | |||

| LED light | |||

| Vacuum pump side channel blower 4kW | |||

| Vacuum pump side channel blower 4,8kW | |||

| Vaccum pump Busch Mink 0312 | |||

| Automatic vaccum field | |||

| Industrial vacuum cleaner (simple) | |||

| Industrial vacuum cleaner (Profi 3kW) | |||

| Industrial vacuum cleaner (Profi 4kW regulated) | |||

| Pneumatic vice | |||

| Saw unit (swiveling) as C-axis | |||

| Carousel changer |

Legend: not available | selectable | Our recommendation (minimum equipment)

Material applications with our models – Overview

| Modell | F+Serie | F+Vertikal | Vertiform | Profi-Serie 1 | Profi-Serie 2 |

| Milling materials: | |||||

| composite materials of plastic or aluminum composite | |||||

| Multiplex-Plywood | |||||

| Acrylic over 50 mm | |||||

| Aluminum up to 10 mm | |||||

| Aluminium over 10 mm | |||||

| Steel and V2A | with small cutter and thin material suitable for occasional milling work | suitable for occasional milling work | with suitable milling spindle, low speed, a lot of power |

Legend: not recommended | recommended | limitted use